Introduction

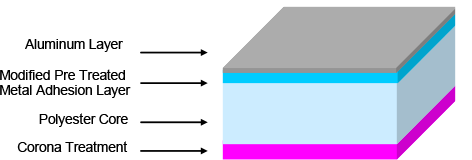

One side vacuum deposited Aluminum on Toray’s modified pre treated surface, side corona treatment. BR incorporates Toray’s newest technology in providing high metal adhesion and high barrier film.Designed for wide range of applications dry~wet.

Features

High metal adhesion even under wet condition

High barrier

Less pinhole, Non-craze metal surface

Heat durability

Typical Structures

OPP / Ink / BR-PET 10UB / Sealant

PET / Ink / BR-PET 10UB / Sealant

ONY / Ink / BR-PET 10UB / Sealant

PET / Ink / BR-PET 10UB / ONY / Sealant

PET / Ink / ONY/ BR-PET 10UB / Sealant

Typical Properties

|

Properties |

|

Unit |

Typical Values |

Measurement method |

|---|---|---|---|---|

|

Thickness |

|

micron |

12 |

|

|

Nominal Yield |

|

m2/kg |

59.5 |

|

|

Tensile strength @ Break |

MD |

MPa |

210 |

ASTM D882 |

|

Young's |

MD |

MPa |

4700 |

ASTM D882 |

|

Elongation @ Break |

MD |

% |

120 |

ASTM D882 |

|

Dimensional Stability |

MD |

% |

2.0 |

ASTM D1204 |

|

COF |

Static |

- |

0.55 |

ASTM D1894 |

|

Wetting |

Metallized |

Dyne/cm |

52 |

ASTM D2578 |

|

Optical Density |

|

- |

30 |

Macbeth |

|

O2TR @23° C, |

Typical |

cc / m2 / day |

0.3 |

ASTM D3985 |

|

WVTR @38° C, |

Typical |

g / m2 / day |

0.3 |

ASTM F1249 |

|

Metal |

DRY |

g / 15mm |

> 300 (500) |

Toray Method |

|

Gloss |

Film |

% |

600 |

ASTM 2457 - 97 |

Application

Confectionery

Liquid potion, Hot filling

Personal care refilled

Lid Stock